Products

Monitoring and Control Solutions

Tracking Solutions

Networking Solutions

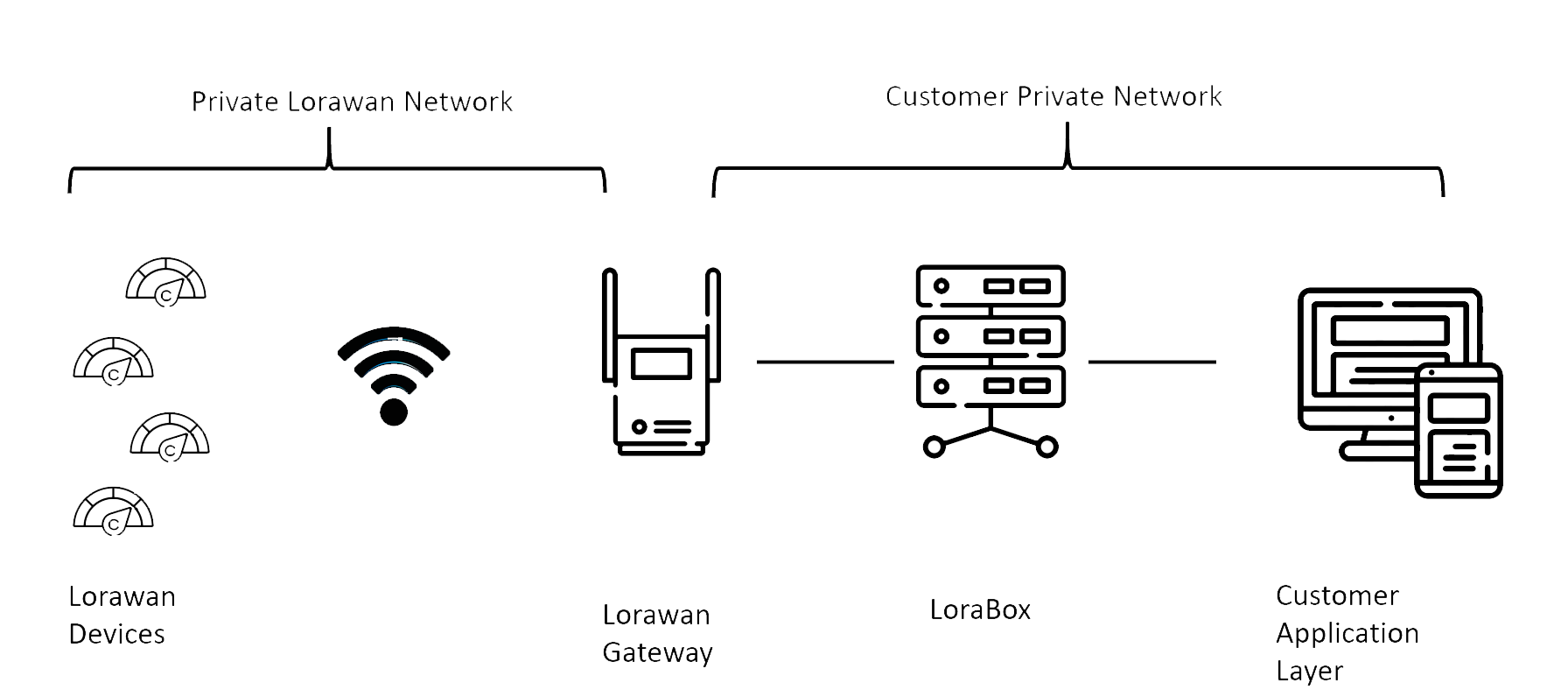

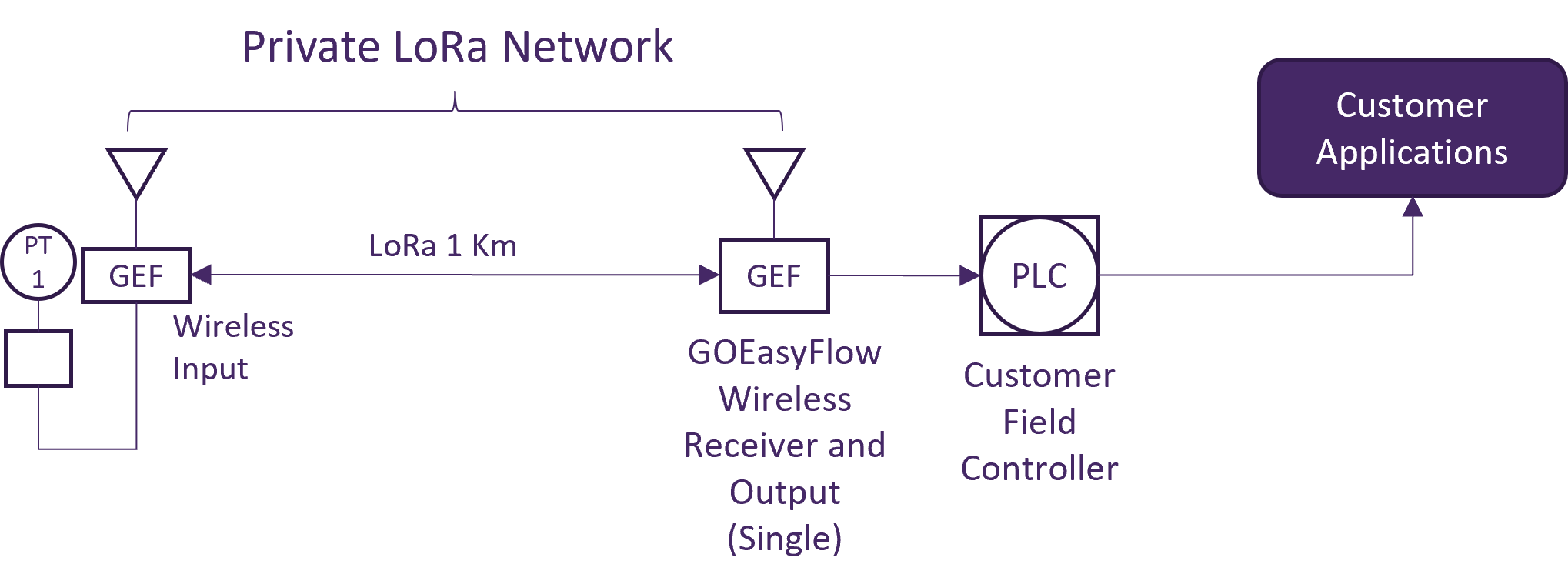

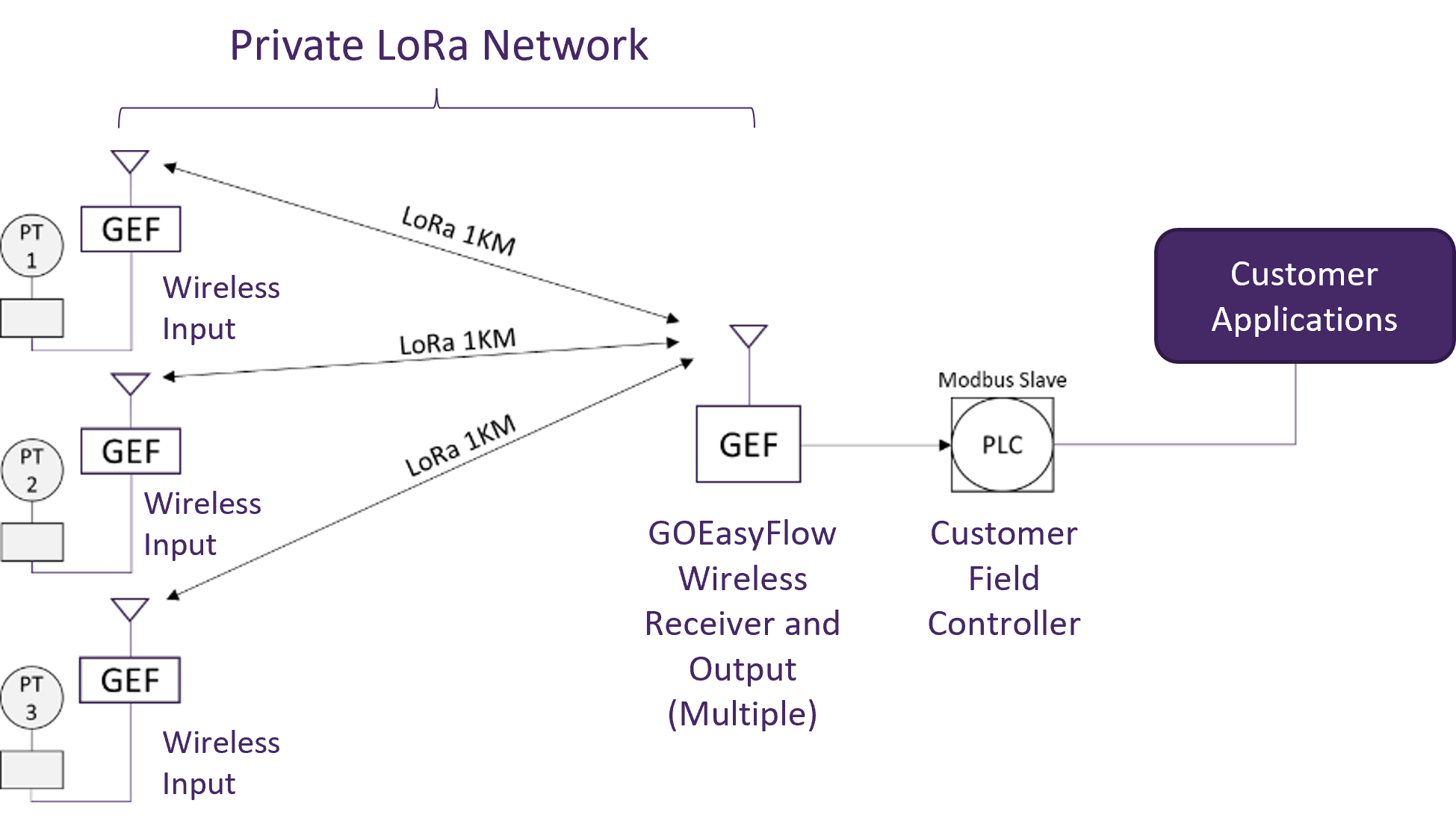

GoEasyFlow solution architecture

LoraBox

- Ready to use Smart LoRaWAN Server that integrates data gathered from smart meters into the GEF Database, providing persistent data storage.

The Lorabox is a data collector and historian, designed and built by GOEasyFlow over the LoRaWAN Network Server infrastructure and adding data persistency to the network server level.

The LoraBox includes the standard functions of a LoRaWAN network server adding data storing in a SQL Server database. This unique feature gives to the metering platform the ability “to remember” data, event if the session between the LoraBox and the customer application infrastructure is lost.

Data Access

LORABOX offers two methods to access the data coming from the sensors network

- Standard MQTT Loraserver subscription method.

- SQL Server data connection.

- One-week data history (default). GEF configurable parameter.

Components

- Loraserver from loraserver.io, personalized for GeF.

- SQL Server Measurement GEF Database

- Lora to SQL Server synchro agent.

- Ubuntu Server 18.04 or higher.

- VM Images for Hyper-V and VMWARE.

- Hyper-V – (required for Lorabox Server).

- Server Box – (required for Lorabox Server).

High Level Architecture

There are two different scenarios for having a working LoraBox according to the database server installation.

The Lorabox Server consists of a physical server running Windows OS Server with Hyper-V roles installed.

The LoraboxVM can be run directly on customer premises without providing a LoraBox Server

Synchro Agent Internal Architecture

Synchro Agent is a component of the Lorabox that takes the data coming from the Loraserver component and save the data to a table. This will allow the Lorabox user to query past records in case of disconnection between the Lorabox and the customer Application Infrastructure.

LoraBox Security

Lorabox offers all the security features provided by the Lorawan standard, using device activation and two layers of 128 AES bit encryption. Also, Lorabox offers TLS encryption over https, MQTT and SQL Server connections.

GOEasyFlow LoRaWAN Piezo resistive industrial differential pressure meter

Features

- Small pressure sensor

- Fully digital signal processing, stable and reliable

- Suitable for large-scale data acquisition and automation control systems

- Double-sided 316 SS metal diaphragm for high corrosion resistance

- Dry gas process

- Lorawan transmission protocol

- Battery operated with up to five years of autonomy with a reading frequency of one hour

Applications

- Oil and Gas industry

- Petrochemical industry

- Power generation

- Water treatment system

- Automation equipment

- Industrial process

Parameters

| Measurement Range | 0-25 KPa | 0-50 Kpa |

| Operating Pressure | 120, 600, 3000 psi | 600, 3000 psi |

| Pressure Type | Differential | |

| Output signal | Lora | |

| Accuracy (%FS) | 0.5 (ASME PTC 19.5 Compliant) | |

| Nonlinearity (%FS) | ≤ 0.5 | |

| Hysteresis (%FS) | ≤ 0.5 | |

| Repetition (%FS) | ≤ 0.5 | |

| Stability | ≤ 0.25 | |

| Temperature Error – Zero (%FS/C) | ≤ 0.02 | |

| Temperature Error – Span (%FS) | ≤ 0.02 | |

| Ambient Temperature | -20 C – 70 C | |

| Power Supply | Li-Ion Battery 3.6 V | |

| Overload (%) | 300 | |

| Life | 9 Million pressure cycles | |

| Load Impedance (W) | ≤ 750 | |

| Response time – primary element (ms) | ≤ 1 | |

| Housing material | 304 SS | |

| Diaphragm material | 316 SS | |

| Pressure port | ½ NPT | |

| Protection | IP66 | |

| Weight | 800g | |

| Enclosure Material | Cast Aluminum | |

| Enclosure Finish | Powder Coating |

GOEasyFlow LoRaWAN wireless thermocouple, thermal resistance industrial temperature meter

Features

- Small temperature sensor

- Fully digital signal processing, stable and reliable

- Suitable for large-scale data acquisition and automation control systems

- Crude oil, wet and natural gas process

- Lorawan transmission protocol

- Battery operated with up to five years of autonomy with a reading frequency of one hour

Applications

- Oil and Gas industry

- Petrochemical industry

- Power generation

- Hydraulic / pneumatic system

- Water treatment system

- Automation equipment

- Industrial process

Parameters

| Measurement Range | 0-200 C |

| Operating Pressure (ASME B40.100) | 9000 psi |

| Output signal | Lora |

| Accuracy (%FS) | 0.5 |

| Nonlinearity (%FS) | ≤ 0.5 |

| Hysteresis (%FS) | ≤ 0.5 |

| Repetition (%FS) | ≤ 0.5 |

| Stability | ≤ 0.25 |

| Temperature Error – Zero (%FS/C) | ≤ 0.02 |

| Temperature Error – Span (%FS) | ≤ 0.02 |

| Ambient Temperature | -20 C – 70 C |

| Power Supply | Li-Ion Battery 3.6 V |

| Overload (%) | 300 |

| Life | 9 Million pressure cycles |

| Load Impedance (W) | ≤ 750 |

| Response time – primary element (ms) | ≤ 500 |

| Housing material | 304 SS |

| Protection tube material | 316 SS |

| Pressure port | ½ NPT |

| Protection | IP66 |

| Weight | 700g |

| Enclosure Material | Cast Aluminum |

| Enclosure Finish | Powder Coating |

GOEasyFlow LoRaWAN Piezo resistive industrial pressure meter

Features

- Small pressure sensor

- Fully digital signal processing, stable and reliable

- Suitable for large-scale data acquisition and automation control systems

- Crude oil, wet and natural gas process

- Lorawan transmission protocol

- Battery operated with up to five years of autonomy with a reading frequency of one hour

Applications

- Oil and Gas industry

- Petrochemical industry

- Power generation

- Hydraulic / pneumatic system

- Water treatment system

- Automation equipment

- Industrial process

Parameters

| Measurement Range | 0-240 psi / 0-800 psi(*) | 0-3000 psi / 0-9000 psi(*) |

| Operating Pressure (ASME B40.100) | 60-180 psi / 200-600 psi(*) | 750-2250 psi / 2250-6750 psi (*) |

| Pressure Type | Gauge | |

| Output signal | Lora | |

| Accuracy (%FS) | 0.5 (ASME PTC 19.5 Compliant as process guages exceeding the requierements for industrial guages) | |

| Nonlinearity (%FS) | ≤ 0.5 | |

| Hysteresis (%FS) | ≤ 0.5 | |

| Repetition (%FS) | ≤ 0.5 | |

| Stability | ≤ 0.25 | |

| Temperature Error – Zero (%FS/C) | ≤ 0.02 | |

| Temperature Error – Span (%FS) | ≤ 0.02 | |

| Ambient Temperature | -20 C – 70 C | |

| Power Supply | Li-Ion Battery 3.6 V | |

| Overload (%) | 300 | |

| Life | 9 Million pressure cycles | |

| Load Impedance (W) | ≤ 750 | |

| Response time – primary element (ms) | ≤ 1 | |

| Housing material | 304 SS | |

| Diaphragm material | 316 SS | |

| Pressure port | ½ NPT | |

| Protection | IP66 | |

| Weight | 700g | |

| Enclosure Material | Cast Aluminum | |

| Enclosure Finish | Powder Coating |

LoRaWAN Gateway

A LoRaWAN gateway receives packets from any LoRaWAN device and send the payload coming from the device to a network server. The gateway communicates with the devices over LoRa, and sends the information using a TCP/IP network connection, normally over ethernet, 3G/LTE and even Wifi.

More than one gateway can receive a packet from a device.

Lorawan Security

Any data solution must ensure that the data sent from a source is only readable by its intended recipient. Lorawan provides a strong encryption mechanism based on two different 128 bits keys at device – network server level and at device – application level.

It lets the data to be transmitted over the wireless network and can only be decrypted by its rightful owner. Each device has its own encryption key to stablish a session with the network server, giving a unique encryption to every single device in the network.

Network Server

This is the top tier of the LoRaWAN architecture. The network server receives information from a group of gateways.

The network server manages device join requests, encryption configuration, categorizing, and data delivery to customers’ applications and systems.

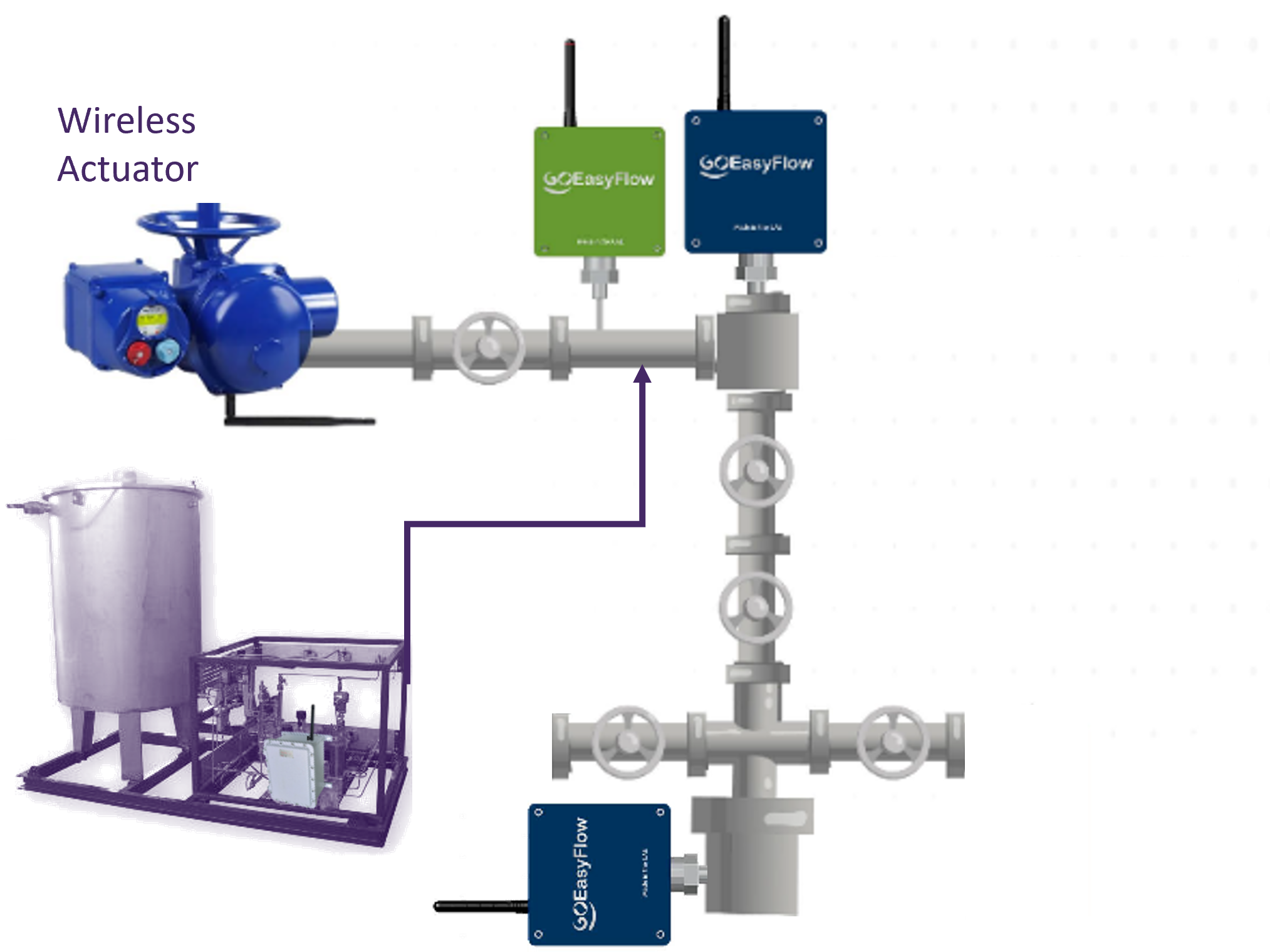

GOEasyFlow Lorawan transciever

– Converting all your existing infrastructure into Fully Wireless

- Engineered in the UAE

- First LoRaWAN Bidirectional Industrial RTU.

- Can connect to all your existing instrumentation already in the field.

- Designed to monitor and control.

- Can control all your existing equipment in the field, such as pumps, motors, actuators, etc.

Wireless Acatuator by Bernard Controls

In collaboration with Bernard Controls, GOEasyFlow developed a fully wireless LoRaWAN actuator with remote control and up to 6 Km transmission range.

- Remote Valve Partial Stroke Testing (PST) capable.

- Real-time status monitoring

- Real-time position control

Wireless Remote Monitoring & Control Solutions

Unmanned Operations, Cost Effective Solutions – Get Remote Surveillance and Control for your field in one month

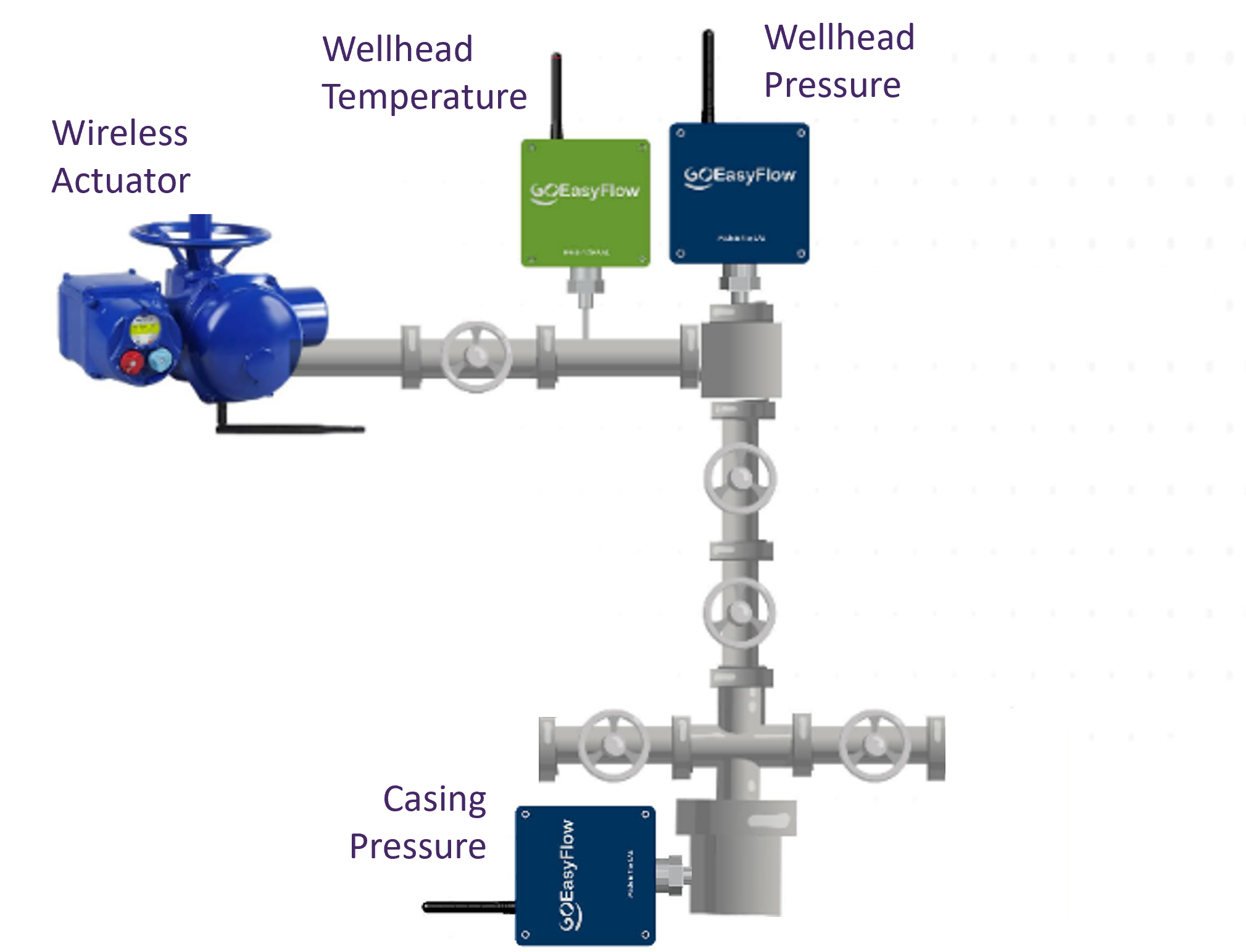

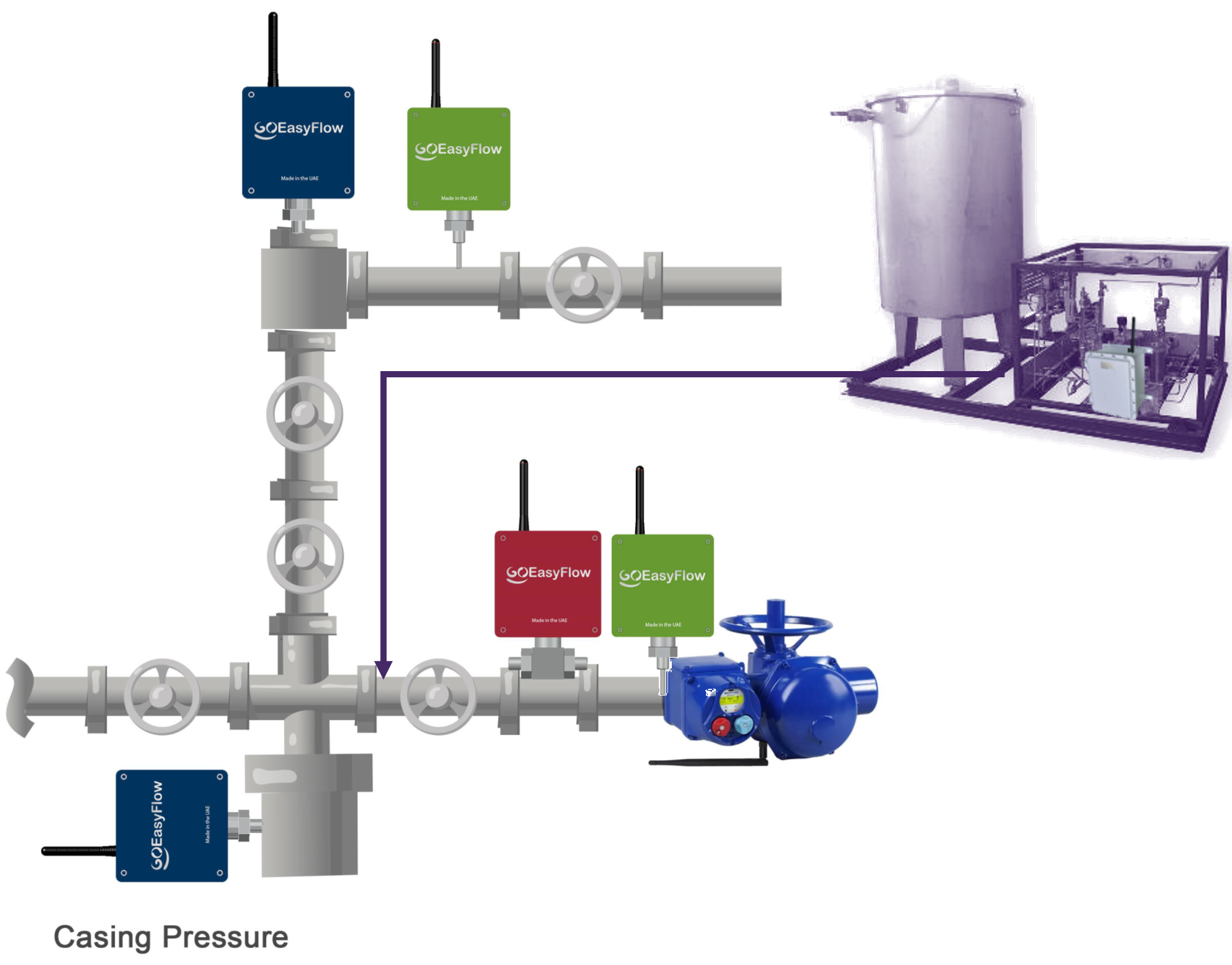

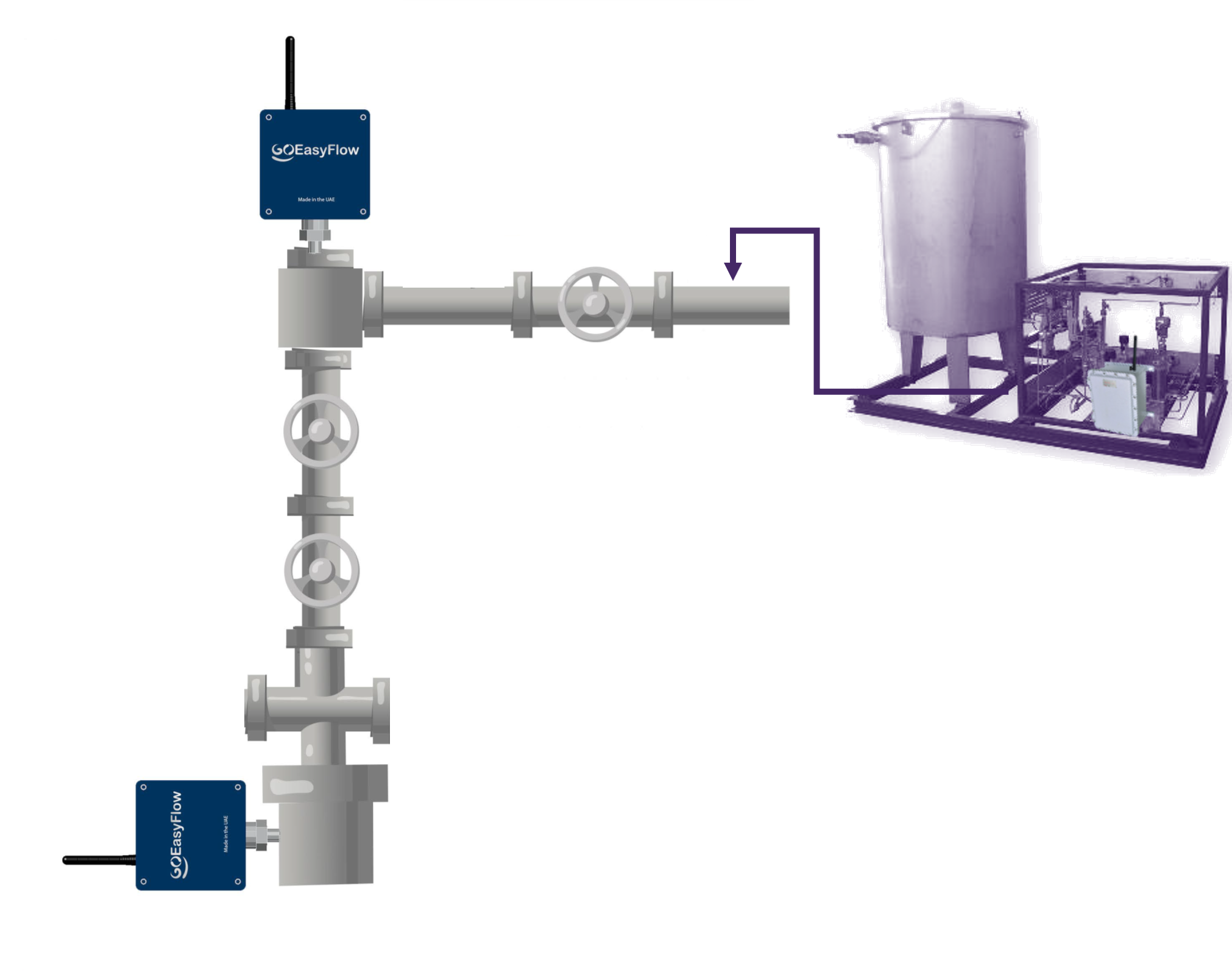

Solution for NF, and IF Wells

More details

Provides wireless remote monitoring of main production parameters:

- Wellhead pressure

- Wellhead temperature

- Casing pressure for completion diagnosis

Provides control of the choke valve to keep an optimum flow rate to maximize enhance the oil recovery.

Allows wireless remote closing the well during the low-pressure stages to re-open when pressure is optimum.

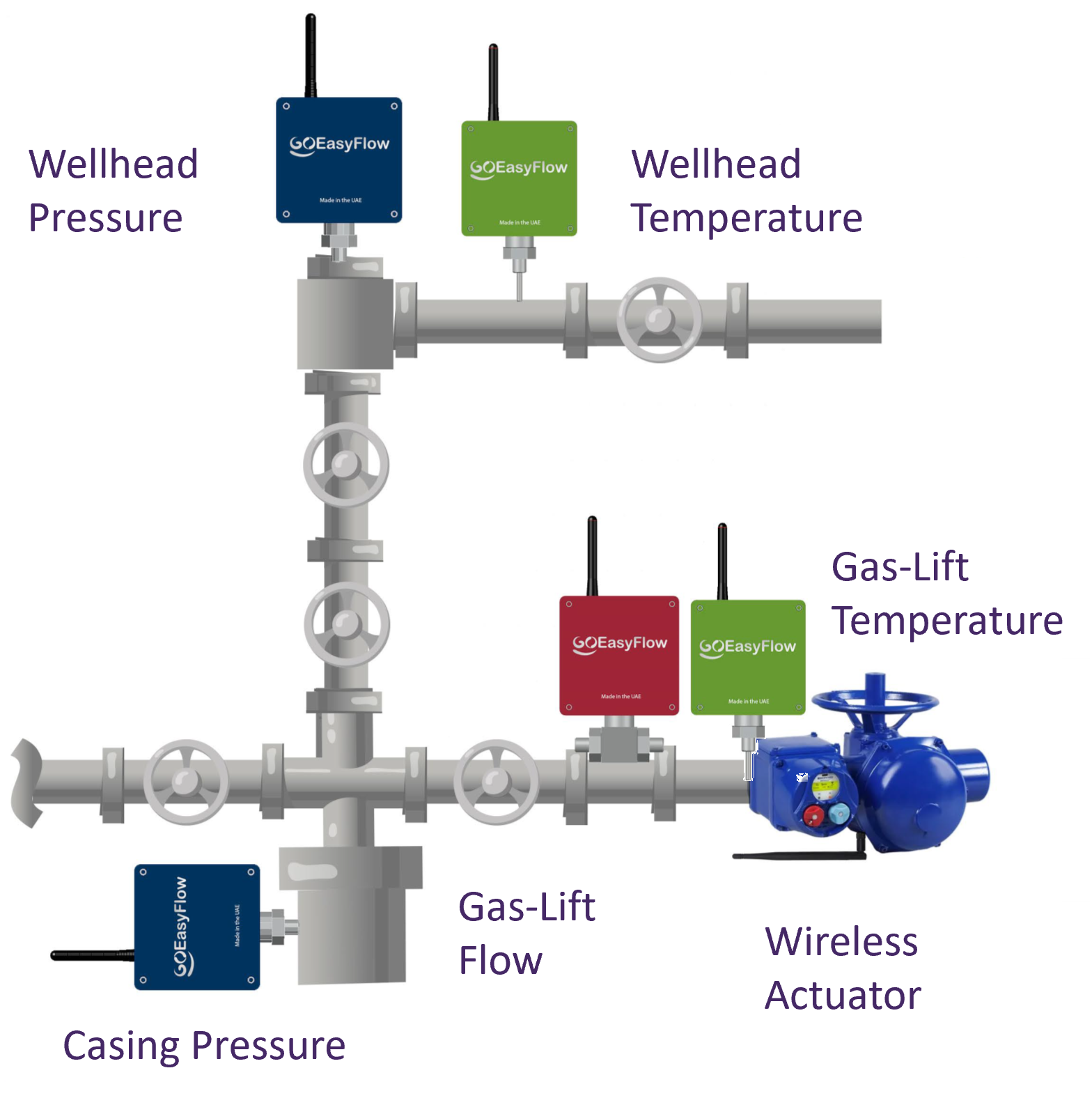

Solution for Gas Lift, NF, and IF Wells

More details

Provides wireless remote monitoring of main production parameters:

- Wellhead pressure

- Wellhead temperature

- Casing pressure for completion diagnosis

- Gas-Lift Flow through an orifice plate

- Gas-Lift Temperature

- Gas-Lift Pressure

Provides wireless control of the Gas-Lift valve to keep an optimum gas supply to maximize and enhance the oil recovery.

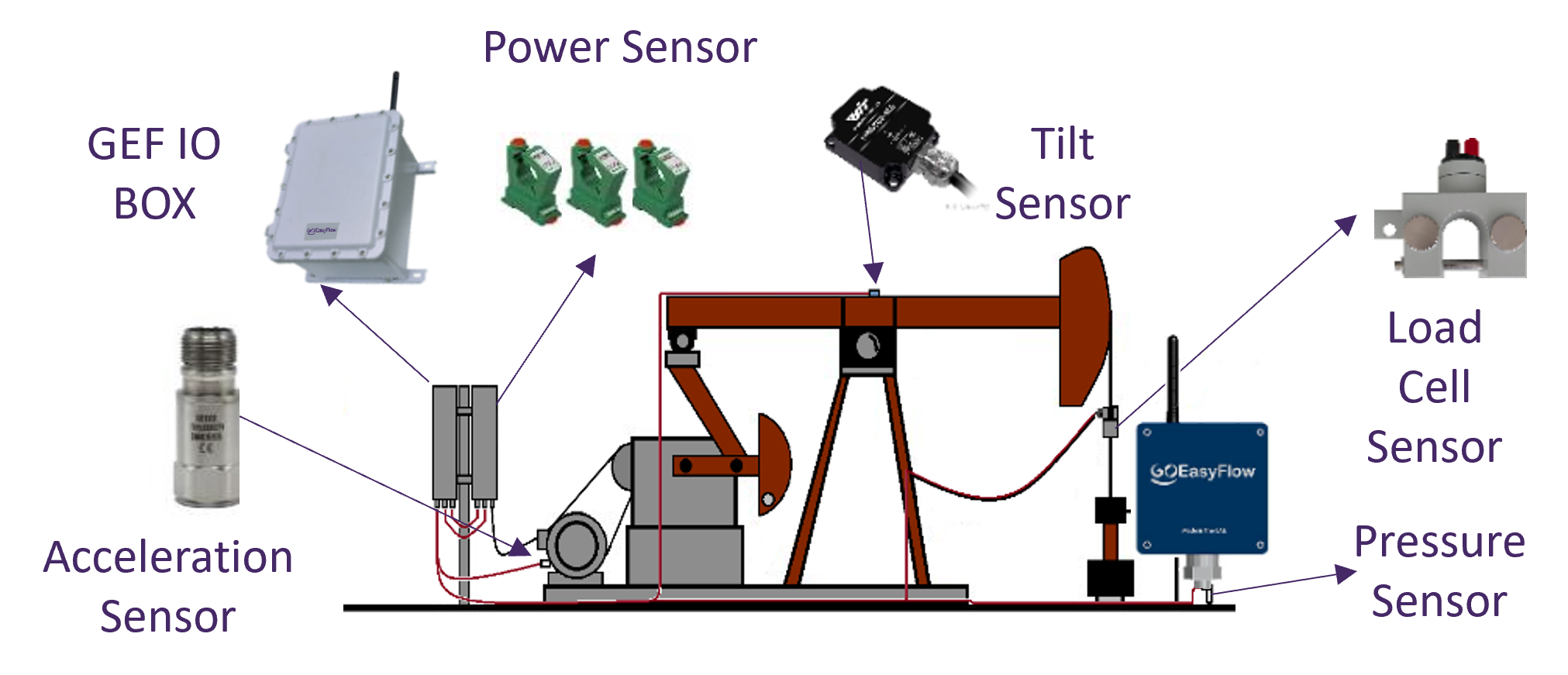

LoRaWAN Wireless Sucker Rod Pump Live Analysis and Control

More details

Provides wireless remote monitoring of main production parameters:

- Load

- Flowline pressure

- Beam angle

- Motor Voltage and Current

- Motor vibration

Provides wireless control of the Motor Controller, allowing the operator to turn the unit on and off.

GOEasyFlow solution offers dynacharts updated every hour, live diagnosis, and well optimization.

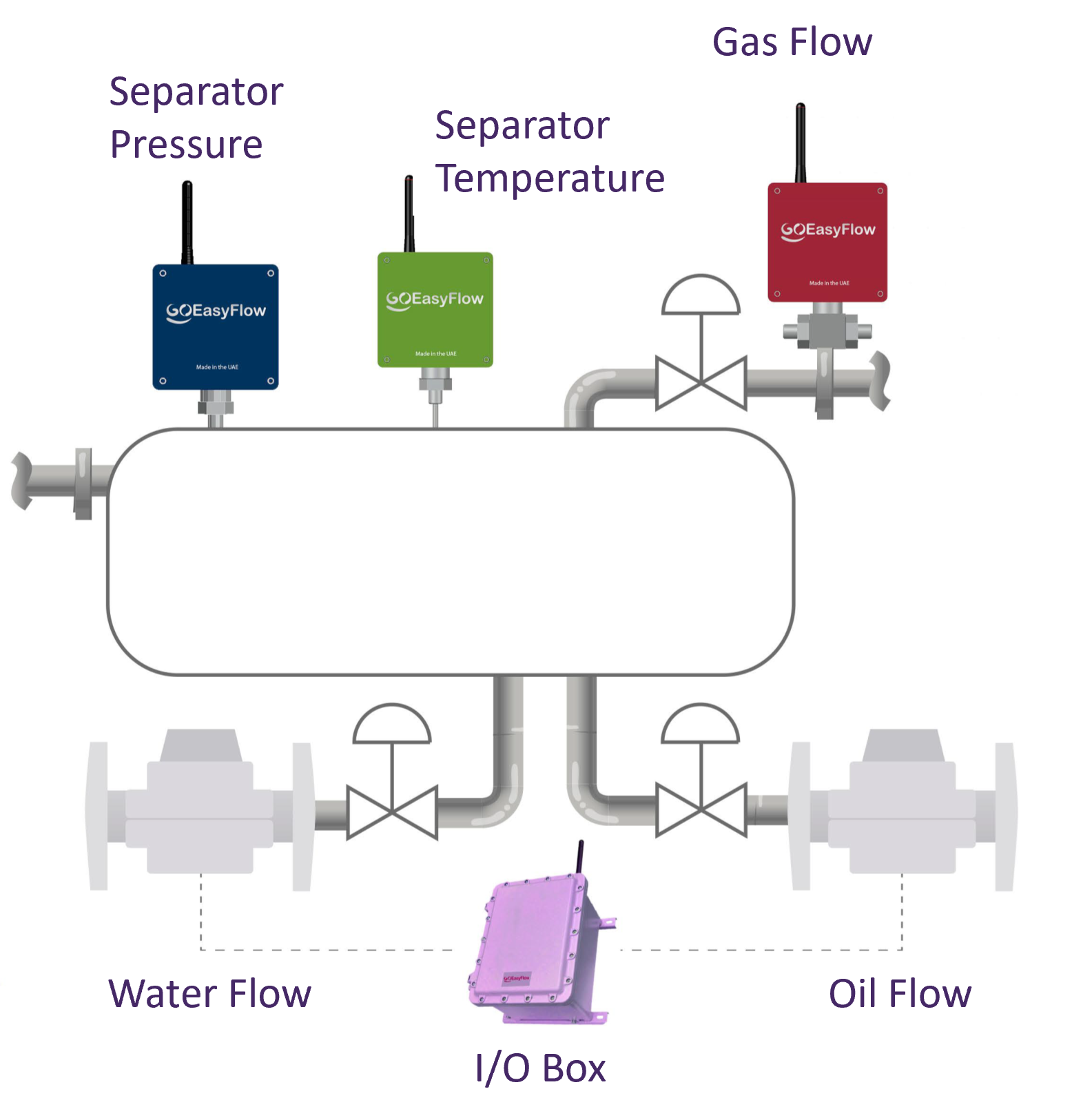

Separator Control for Remote Well Testing

More details

Provides wireless remote monitoring of main production parameters:

- Separator pressure

- Separator temperature

- Gas flow

- Water flow

- Oil flow

GOEasyFlow solution can be implemented in any three-phase separator, converting the unit into a live multiphase flow meter. Powered by GOEasyFlow algorithms to obtain accurate compositional measurements.

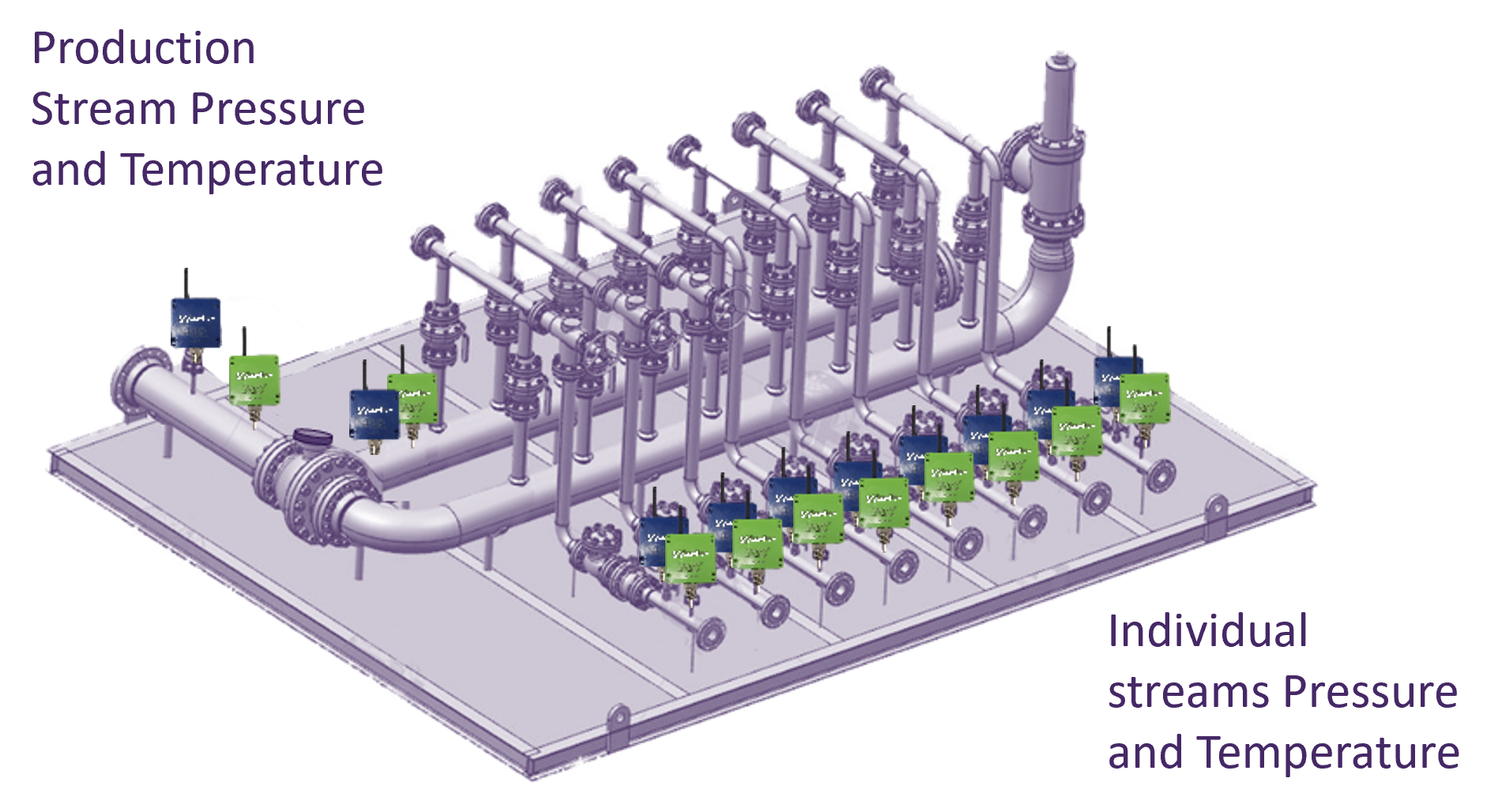

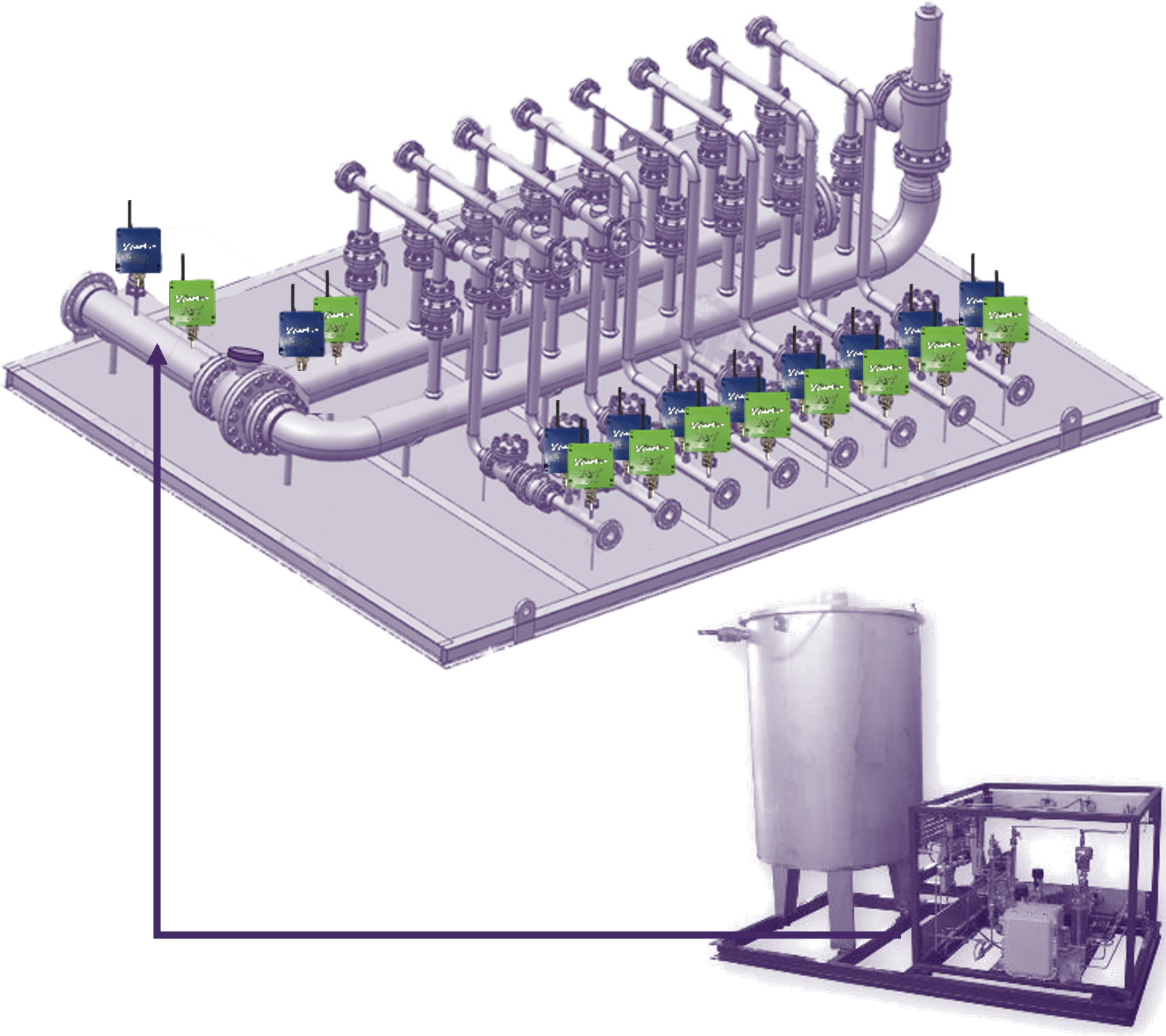

Manifold Monitoring

More details

Provides wireless remote monitoring of main production parameters:

- Production stream pressure

- Production stream temperature

- Test stream pressure

- Test stream temperature

- Individual pressure

- Individual temperature

GOEasyFlow solution can be implemented in any manifold to provide maximum information about the behavior of the wells to optimize production, run oil back allocation models, and integrate data into node analysis workflows.

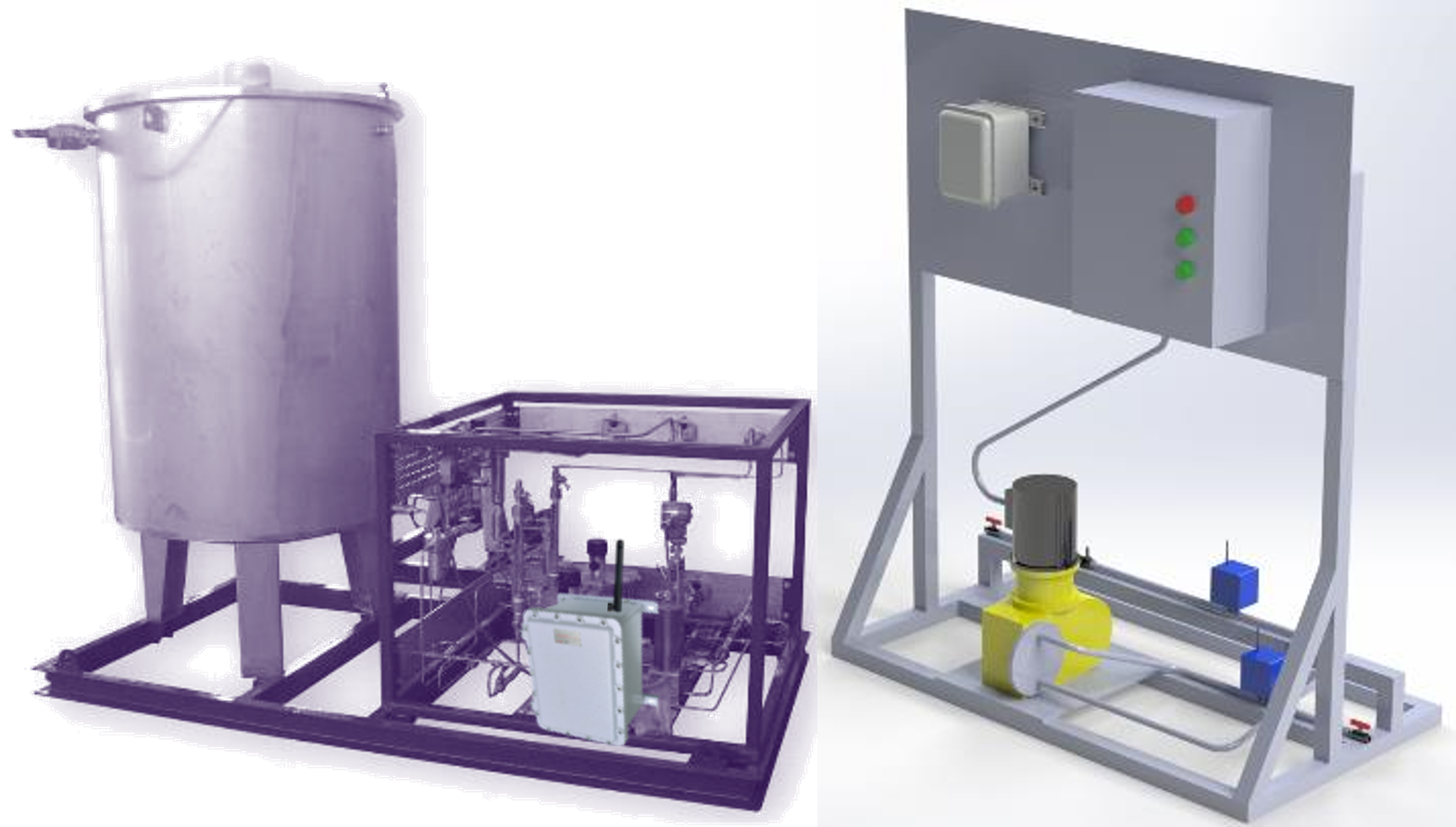

Chemical Injection Module

More details

Fully customizable chemical injection module provided with or without tank and all the instrumentation required to monitor, control, and optimize the injection rate.

Suitable for injection of:

- Hydrates inhibitors

- Corrosion inhibitors

- Surfactants

- Scale inhibitors

- Biocides

- Oxygen scavengers

- Polymers

- H2S scavenger, among others.

Gas Lift Chemical Injection

More details

Provides wireless remote monitoring and control of the injection rate for chemicals such as:

- Hydrates inhibitors

- Corrosion inhibitors

- Surfactants

- Scale inhibitors

Water Injection Lines Chemical Injection

More details

Provides wireless remote monitoring and control of the injection rate for chemicals such as:

- Biocides

- Oxygen scavengers

- Scale inhibitors

- Corrosion inhibitors

- Surfactants

- Polymers

Flow Line Chemical Injection

More details

Provides wireless remote monitoring and control of the injection rate for chemicals such as:

- Surfactants

- Polymers

- Scale inhibitors

- Corrosion inhibitors

- Biocides

- H2S scavenger

Manifold Chemical Injection

More details

Provides wireless remote monitoring and control of the injection rate for chemicals such as:

- Surfactants

- Polymers

- Scale inhibitors

- Corrosion inhibitors

- Biocides

- H2S scavenger

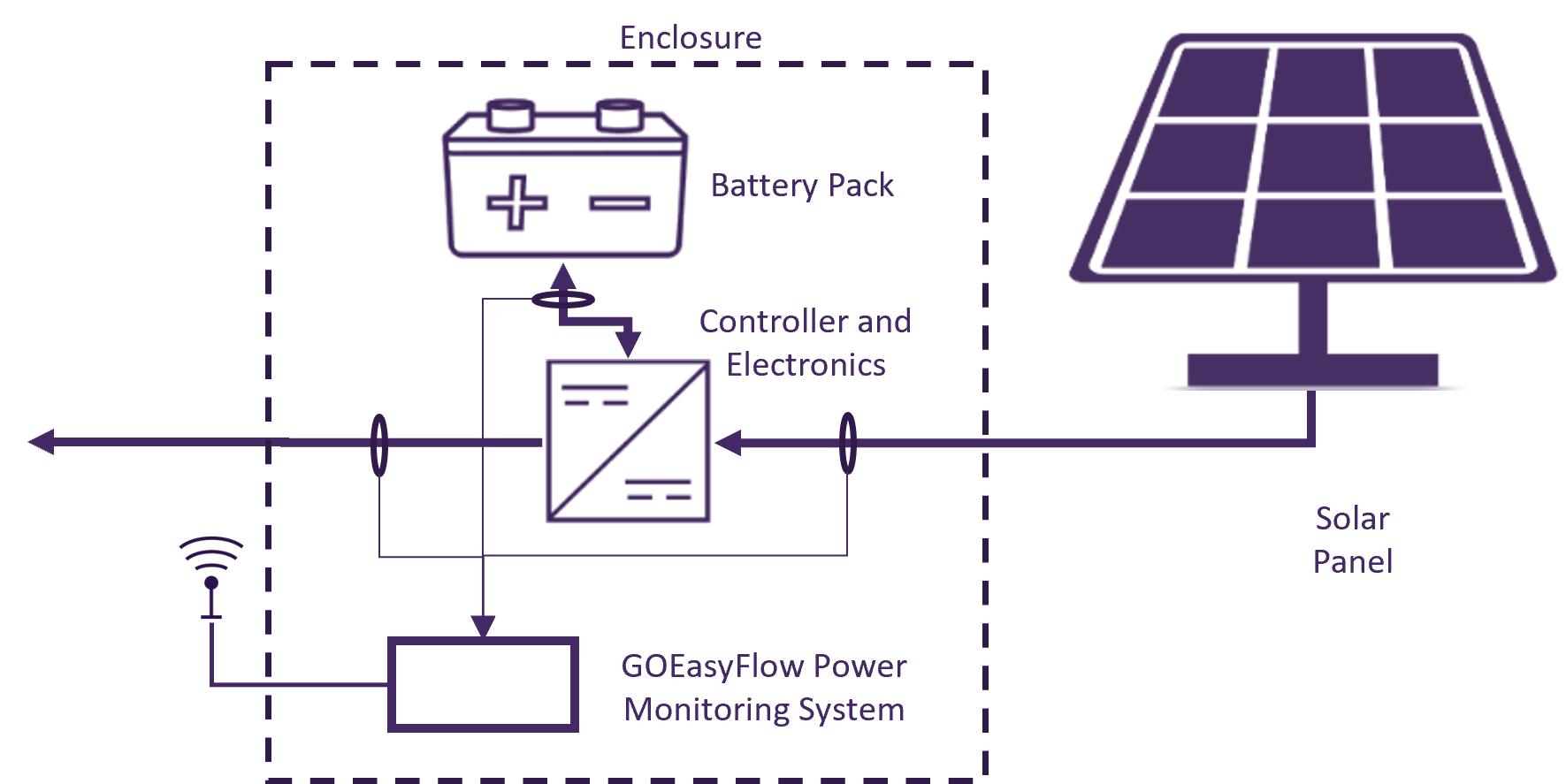

Provision, Monitoring and Control of Electricity from Solar Panel

More details

Provides a source of energy from solar panels to power up processes and telecommunication equipment.

In addition, the system provides health parameters, such as:

- Solar panel voltage

- Battery voltage

- Battery current

- Battery temperature

- Voltage regulator output

Provision, Monitoring and Control of Electricity from Solar Hydrogen

More details

Provides a source of energy from hydrogen to power up processes and telecommunication equipment.

In addition, the system provides health parameters, such as:

- Fuel cell voltage

- Battery voltage

- Battery current

- Battery temperature

- Hydrogen bottle pressure

- Voltage regulator output

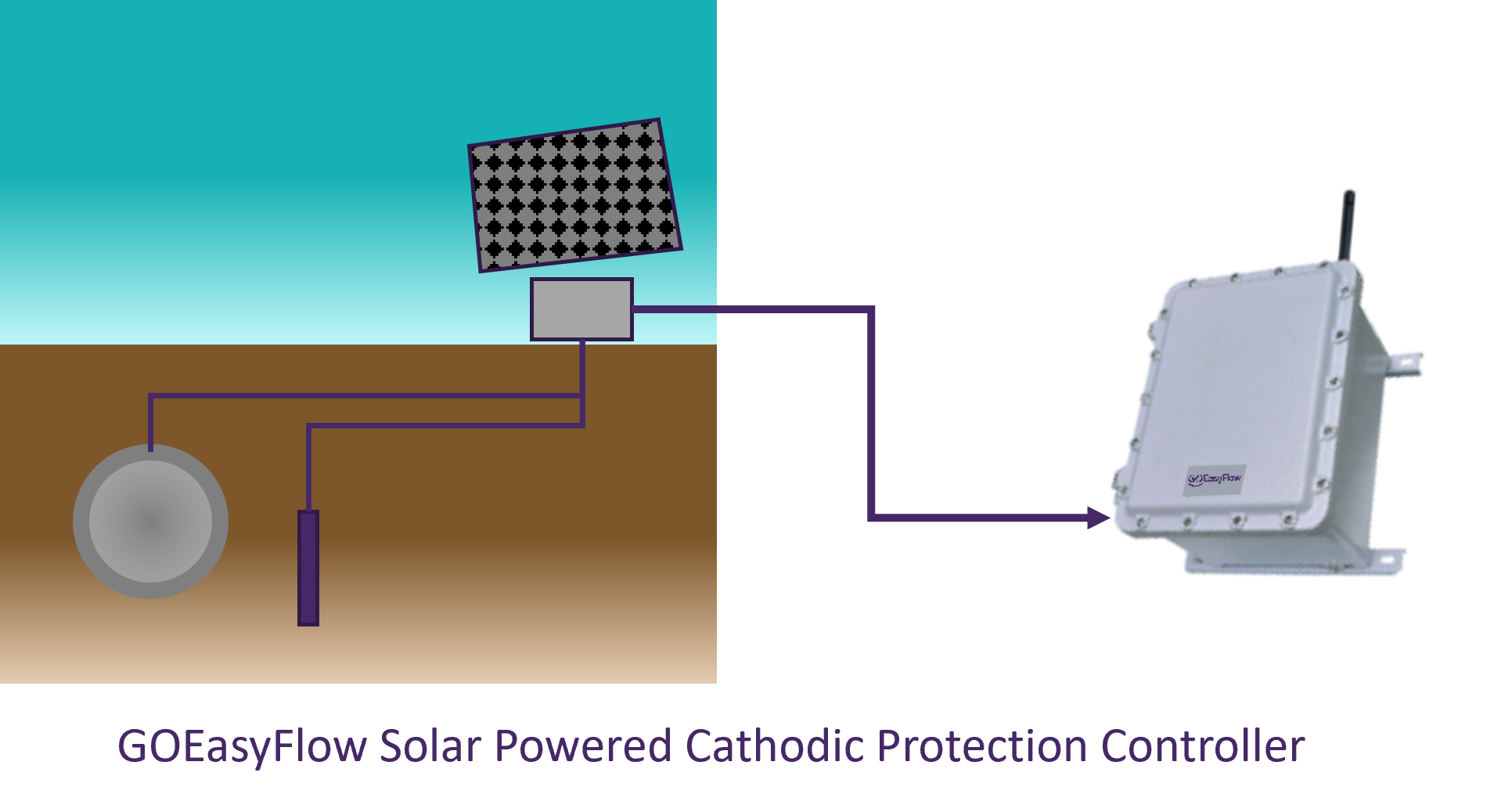

Cathodic Protection Monitoring

More details

Measures corrosion variables:

-

Cathodic protection controller output voltage (DC)

- Cathodic protection controller output current(DC)

- Cathodic protection controller half-cell voltage

- Battery temperature

- Voltage regulator output

As well as system health variables:

- Solar panel voltage

- Battery voltage

- Battery current

- Battery temperature

- Voltage regulator output

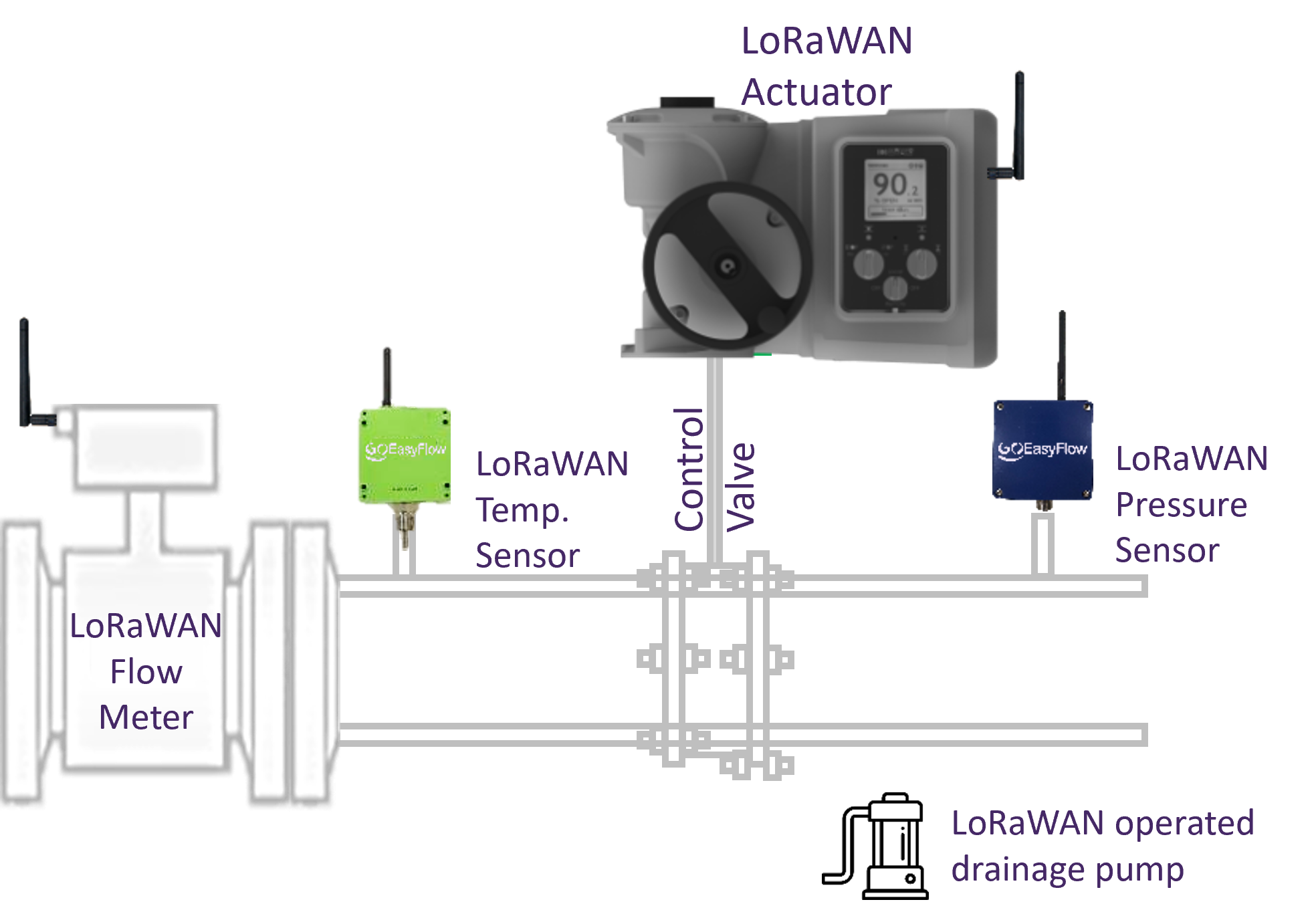

Water Network Monitoring and Control

More details

- No cabling for communication is needed

- Self-powered

- Low cost/time for installation (No cabling)

- Remote Real-Time Monitoring and Control

- Automatic drainage when flooded

- Can be installed in current chambers with the existing instrumentation (Modbus and Analog Signals can be converted into LoRaWAN using GOEasyFlow I/O Box)

Flow Assurance – Non-Intrusive Tools

More details

- Flow assurance monitoring for existing pipelines involves continuous monitoring of parameters such as temperature, pressure, flow rate, and fluid composition. This monitoring is carried out using monitoring equipment installed along the pipeline, which sends data to a control room where it is analyzed and evaluated.

Flow assurance monitoring aims to identify any issues that could potentially impact pipeline integrity or cause disruption to the flow of hydrocarbons. Any deviations from expected values are investigated and corrective actions are taken to ensure the safe and efficient operation of the pipeline. This monitoring process is ongoing, and any changes or updates to the pipeline design or operating conditions are taken into account to ensure optimal flow assurance.

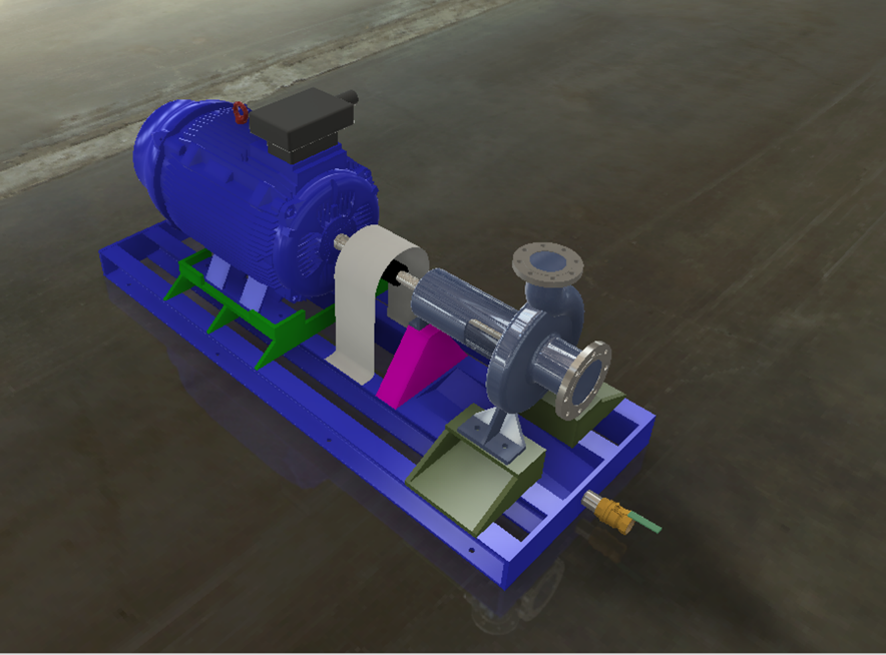

Smart Pumps

More details

GOEasyFlow provides a range of API 610 OH1 smart pumps with the following capabilities:

- Process variables monitoring : Inlet pressure, outlet pressure, liquid rate, motor vibration, motor voltage, motor current, active/reactive power, energy, harmonics, and power factor.

- Self-diagnosis and alarm.

- Ranges 50 Hp to 200 Hp

Tracking Solutions

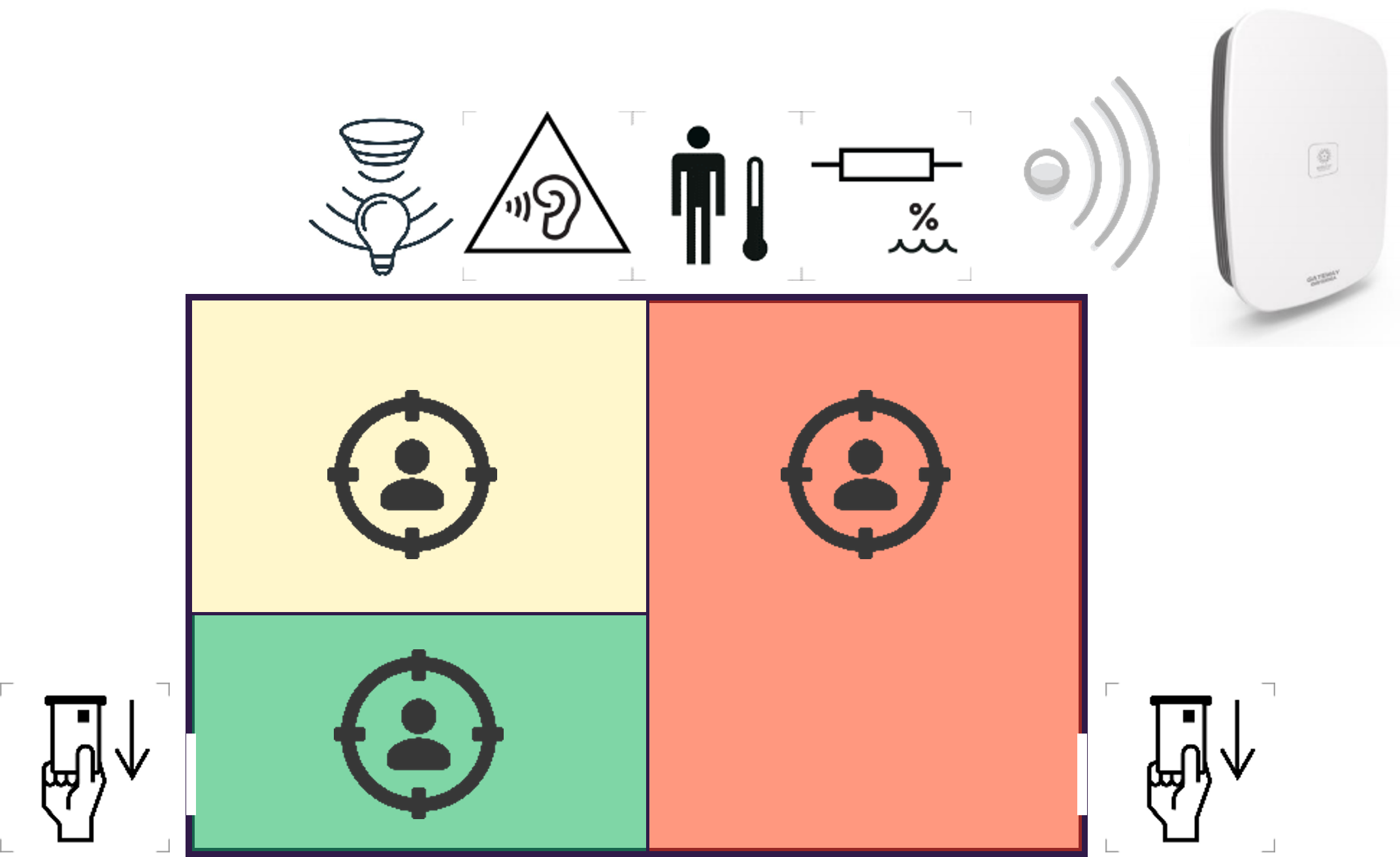

Personnel Monitoring/Tracking

More details

Wireless personnel tracking using the LoRaWAN technology provides a range of advantages for industrial areas, such as precise location tracking, virtual fencing to prevent unauthorized access, and real-time monitoring of ergonomics metrics like lighting level, temperature, humidity, and noise level.

This technology allows for better safety, productivity, and decision-making in industrial environments, with data collected providing actionable insights for resource allocation and process optimization.

Asset Tracking

More details

Wireless asset tracking using LoRaWAN technology provides precise location tracking of assets, equipment alarms, vibration monitoring, power consumption, machinery temperature, and hours of operation, among other variables.

This technology enables real-time data collection, allowing for predictive maintenance, process optimization, and improved equipment uptime. As a result, industrial operations can benefit from increased efficiency, reduced downtime, and enhanced productivity.

Networking Solutions

Telemetry P2P

More details

Point-to-point telemetry offers a reliable and secure communication channel with low interference and data loss, making it ideal for field applications such as remote monitoring of process parameters. It can be more efficient and cost-effective than other forms of telemetry, requiring fewer resources and optimized for specific use cases.

Available 4-20 mA, 0-5 V, Pulse, Relay and Modbus RTU.

Telemetry MP2P

More details

Multipoint-to-point telemetry allows for multiple transmitters to communicate with one receiver, making it ideal for applications where data needs to be shared across multiple locations or devices. This form of telemetry is often more flexible than point-to-point telemetry, allowing for dynamic changes to the network topology. This can be useful in applications such as wireless sensor networks, smart grid systems, or environmental monitoring networks.

Available 4-20 mA, 0-5 V, Pulse, Relay and Modbus RTU.

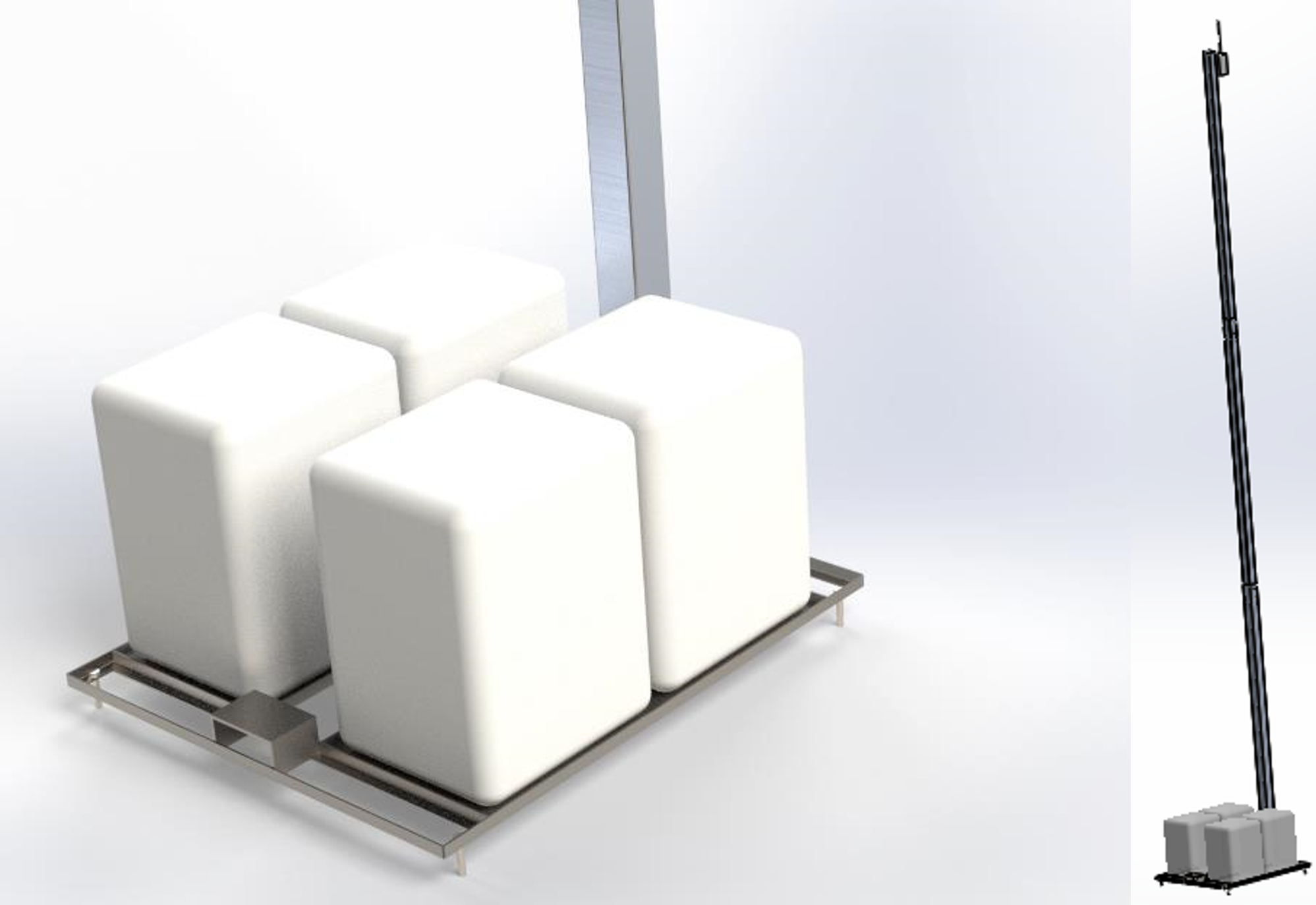

Portable Telecom Station

More details

- Provides a LoRaWAN platform to read all variables using GOEasyFlow Wireless Transmitters and I/O Box. The unit can provide bi-directional communication with up to 16,000 devices within range.

- Full Telecom solution providing Monitoring and Control. Offered pre-assembled, ready to deploy for two people in 2 hours.

- No civil construction required.

- Can be deployed in the field Onshore and Offshore.

- Live data transfer to the control room through the customer’s network, physical connection, Intranet, GSM, P2P, or Satellite.

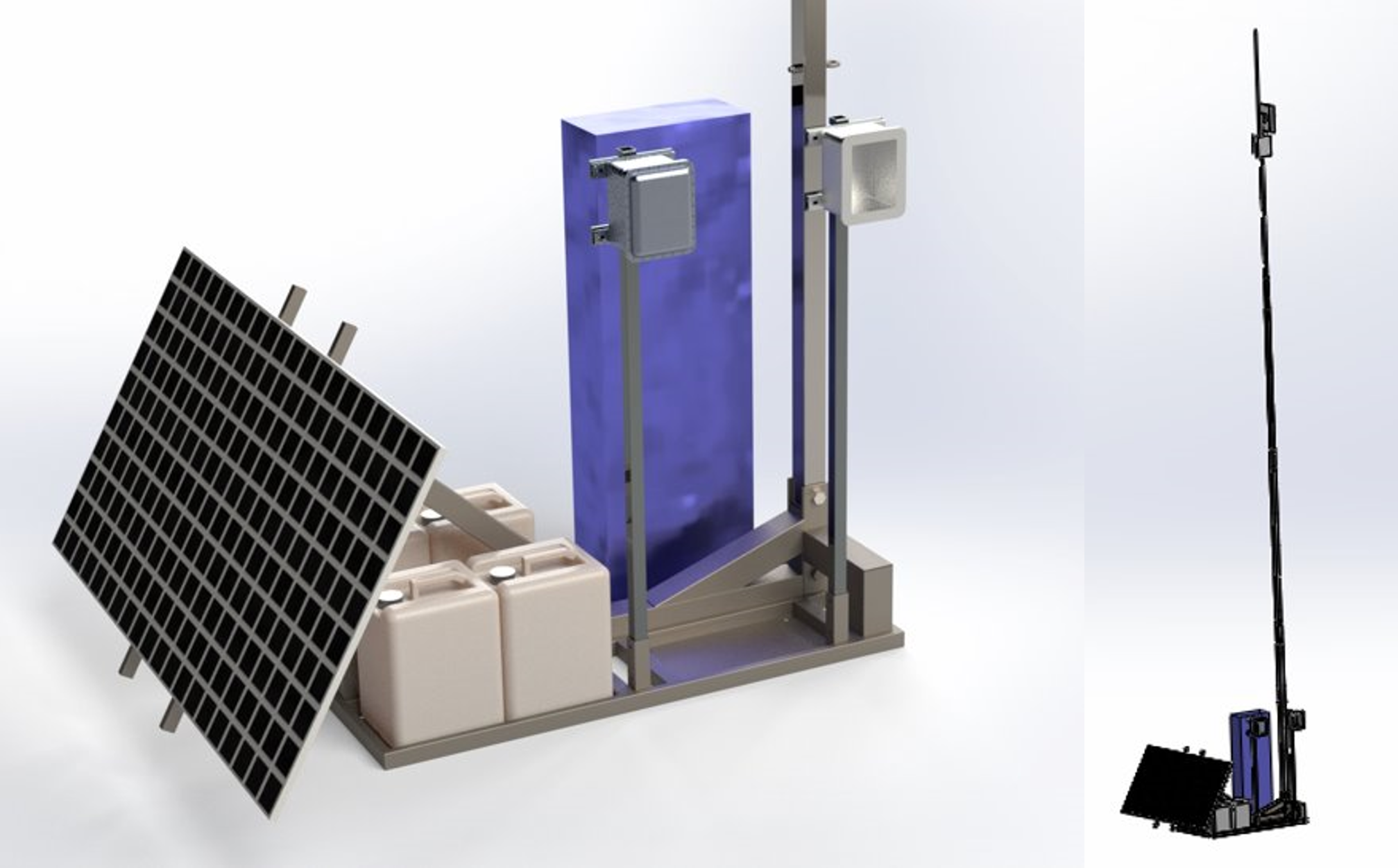

Portable Telecom Station with Solar Power

More details

- Provides a LoRaWAN platform to read all variables using GOEasyFlow Wireless Transmitters and I/O Box. The unit can provide bi-directional communication with up to 16,000 devices within range.

- Full Telecom solution providing Power, Monitoring and Control. Offered pre-assembled, ready to deploy for two people in 4 hours.

- No civil construction required.

- Can be deployed in the field Onshore and Offshore.

- Live data transfer to control room through customer’s network, physical connection, Intranet, GSM, P2P, or Satellite.

Safety Solutions

Full LoRaWAN ESD and Monitoring System

Contact Us

info@goeasyflow.com – +971 4 572 6766

Office

Reef Tower, Office 1906, JLT, Dubai, United Arab Emirates